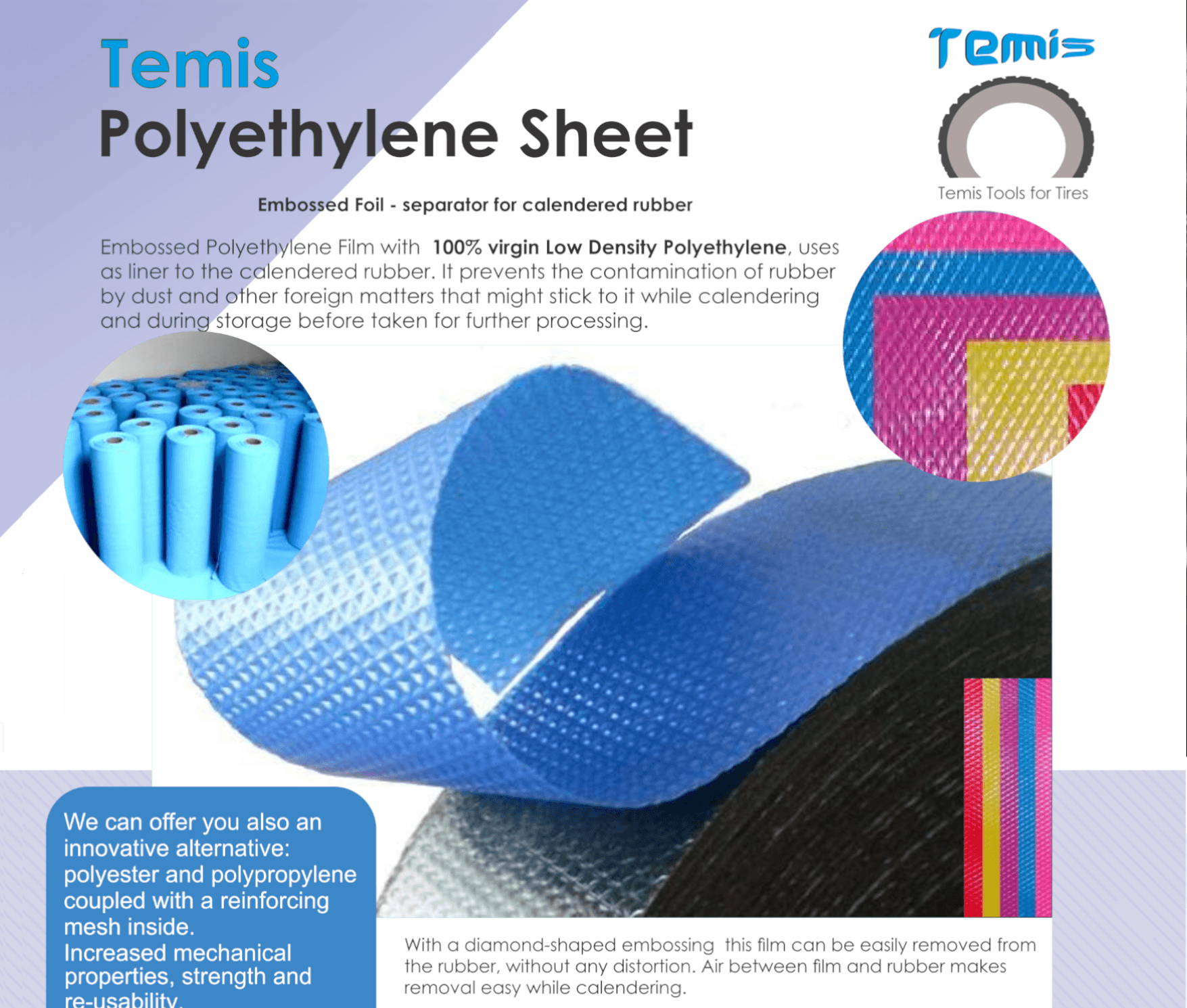

Polyethylene Embossed Foil

Rubber Separator for Tire Manufacturers, Vulcanized Rubber and Composite Materials

Tire and Vulcanized Rubber Production

The embossed polyethylene film is used as a release layer in the processing of rubber compounds, including:

- Tire production: inner liner, sidewall and rubber compound separator

- Easy storage for calendered rubber

- Separator for extruded rubber sheets

Composite MATERIALS : PREPREG SEPARATOR

In composite materials, the embossed polyethylene film is used in as a separator for prepreg materials. It prevents adhesion between the sheets of prepreg materials.

- Clean, defect-free prepreg sheets

- Easy to store, easy to detach

- Better prepreg quality

Benefits of Polyethylene Embossed Foil

Improved Product Quality

Protects from abrasion, contamination and foreign substances to ensure a smooth, uniform surface finish and enhance overall product quality

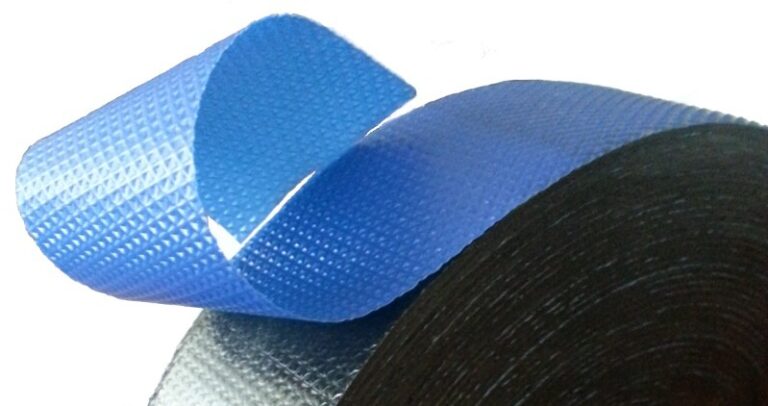

Enhanced Mold Release

The embossed surface creates a barrier that facilitates easy release, minimizing production downtime and waste.

Increased Efficiency

Streamlines the manufacturing process, reducing the need for additional release agents or manual interventions.

Cost-Effective Solution

In the rubber calendering process it is used as a separator of rubber sheets. It does not stick or melt and is easy to remove.

Technical Specifications: Polyethylene Embossed Foil

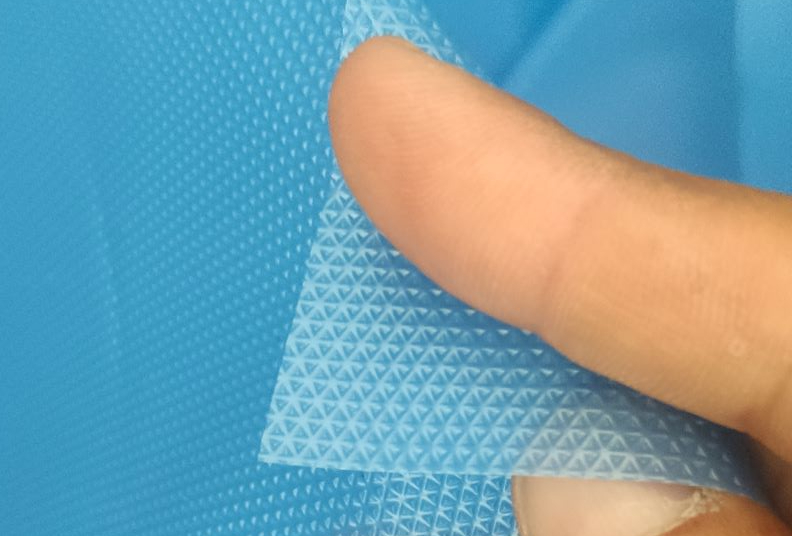

- PRODUCT: Diamond embossed PE film

- MATERIALS: LDPE + MDPE + colour masterbatch (we do not use any silicone, fatty acids or metallic salts of fatty acids)

-

DIMENSIONS AND TOLERANCES:

- Thickness before embossing (DIN 53370): 0,08 – 0,10 mm ± 12 %

- Thickness after embossing (DIN 53370):

• 0,08 mm -> 0,320 - 0,380 mm

• 0,09 mm -> 0,330 - 0,400 mm

• 0,10 mm -> 0,340 - 0,410 mm

- Width:

• 500 - 800 mm ± 5 mm

• 801 - 1200 mm ± 7 mm

• 1201 - 1600 mm ± 10 mm -

PHYSICAL CHARACTERISTICS:

- Melting point: 100 - 110 °C

- Tensile strength:

• MD: > 20 MPa

• TD: > 19 MPa - Elongation at break:

• MD: > 250 %

• TD: > 350 % -

PACKAGING:

- Core: carton, 76 mm

- Pallet: per customer request

* Reels are delivered on a pallet and wrapped with stretch film. Each reel is marked with a control label; each pallet is equipped with a numbered pallet sheet.

STORAGE

-

Storage conditions:

products must be stored in a dry area and should not be exposed to direct sunlight. Recommended storage conditions include temperatures between 10 °C and 25 °C and relative humidity between 40 % and 60 %. Any deviations in temperature and humidity may lead to altered product properties. - Shelf life: In cases described above regarding the recommended storage conditions, the estimated shelf life is 1 year from the date of production.

Mechanical properties

- Machine direction >14,7 MPa (N/mm2)

- Transversal direction >10,8 MPa (N/mm2)

- Machine direction: >150 %

- Transversal direction: >250 %

- Melting point: 90-130 °C

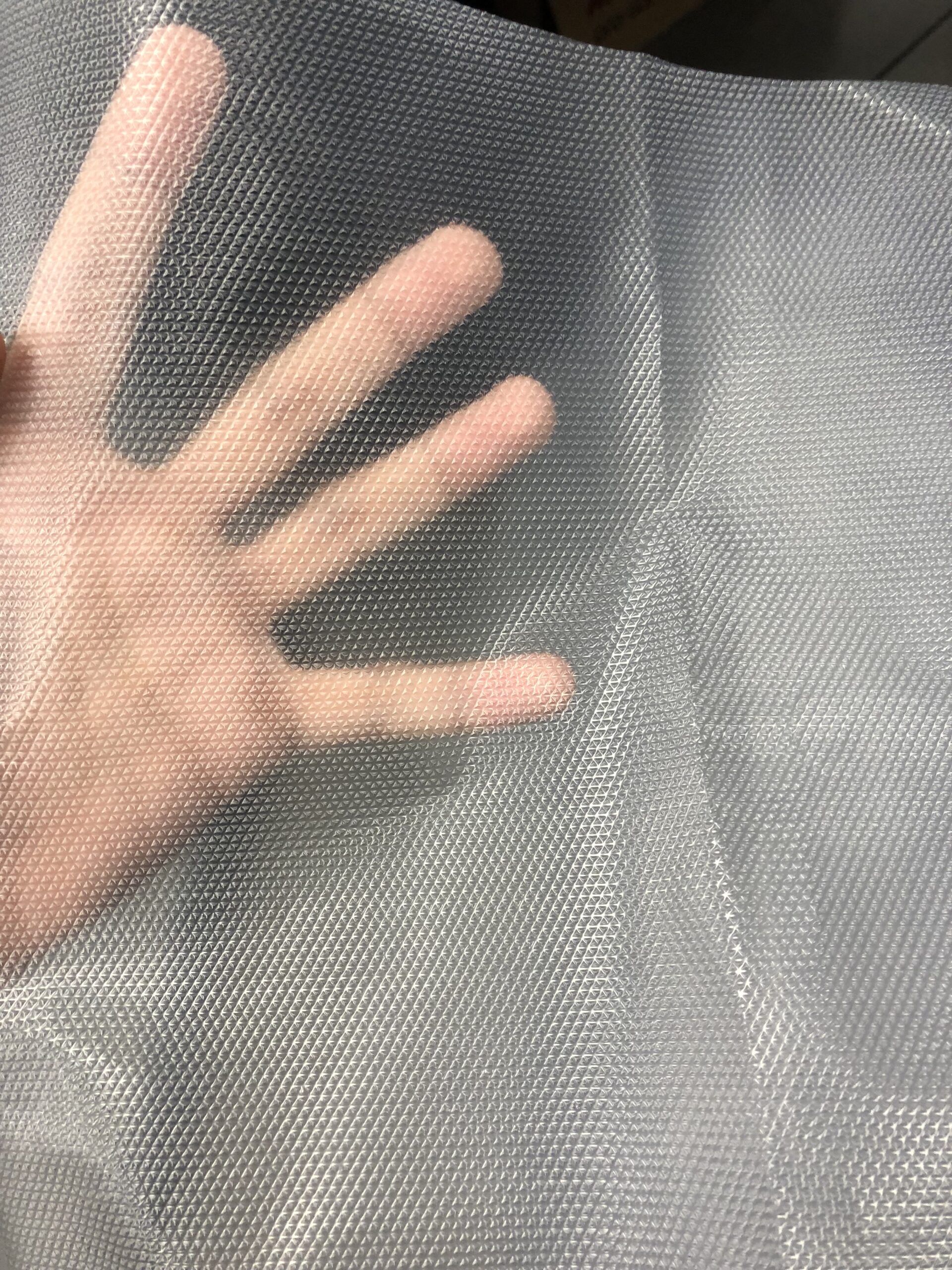

An environmentally-friendly alternative: polyester-based multilayer film

This new release liner is a stiff polyester-based multilayer film that is reinforced internally with a high tear resistance mesh; the film is then embossed in a second step to increase its release properties. With very high tear resistance, excellent mechanical qualities and release properties for processes that require a stiffer film.

High Mechanical Strength and Tear Resistance

Excellent release qualities for rubber

Costs less - can be reused 20-25 times more than conventional products

More environmentally friendly than standard polyethylene liner

Preserves fresh rubber sheets, without creases or deformation

No polluting substances, fraying or bagging

Contact Us

Have a question or want to explore a collaboration? Fill out the form below and we’ll reply shortly.